Revolutionizing Microparticle Fabrication Through 3D Printing

Kernkonzepte

The author argues that traditional microparticle fabrication techniques have limitations in shape control, and introduces a new high-throughput 3D printing method to address this issue.

Zusammenfassung

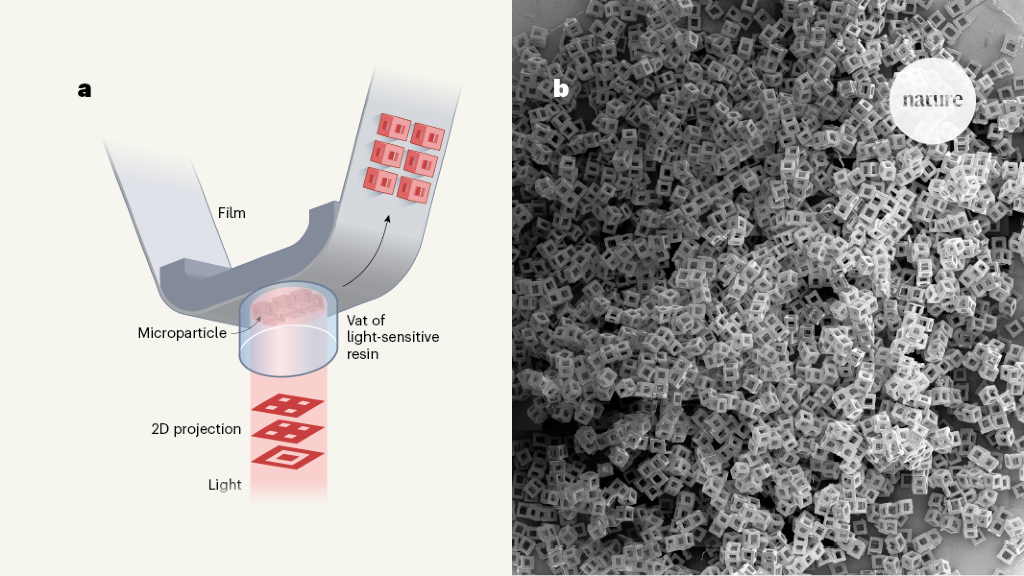

Micrometre-sized particles play a crucial role in various technologies, but optimizing their fabrication has been a challenge. Current strategies involve bottom-up and top-down approaches, each with its own limitations. However, Kronenfeld et al. propose a novel 3D printing method in Nature that promises rapid production of microparticles with complex geometries, potentially revolutionizing the field.

Zusammenfassung anpassen

Mit KI umschreiben

Zitate generieren

Quelle übersetzen

In eine andere Sprache

Mindmap erstellen

aus dem Quellinhalt

Quelle besuchen

www.nature.com

3D printing enables mass production of microcomponents

Statistiken

Micrometre-sized particles are key elements of several technologies.

Bottom-up approaches enable high-throughput production but offer limited control over particle geometry.

Top-down strategies can overcome the shortcomings of bottom-up techniques by providing pathways towards improved shape control.

Traditional methods produce only 2D or simple 3D particles.

Kronenfeld et al. present an innovative high-throughput fabrication method for rapidly 3D printing microparticles with complex geometries.

Zitate

Wichtige Erkenntnisse aus

by Christoph A.... um www.nature.com 03-13-2024

https://www.nature.com/articles/d41586-024-00492-z

Tiefere Fragen

How might the introduction of 3D printing impact the cost-effectiveness of microparticle fabrication

The introduction of 3D printing in microparticle fabrication can significantly impact cost-effectiveness. Traditional methods often involve complex processes with high material waste and labor costs. With 3D printing, the ability to rapidly produce microparticles with intricate geometries allows for more efficient use of materials and reduced production time. This streamlined process can lead to cost savings by minimizing material wastage, lowering labor expenses, and optimizing overall production efficiency.

What potential challenges could arise from widespread adoption of this new fabrication method

Despite its numerous benefits, widespread adoption of 3D printing in microparticle fabrication may pose certain challenges. One potential issue is the need for specialized equipment and expertise to operate advanced 3D printers effectively. Additionally, ensuring consistent quality control throughout the fabrication process could be a challenge due to the complexity of producing microscale particles with intricate designs. Moreover, there might be regulatory hurdles related to certifying these new manufacturing techniques for specific applications.

How can advancements in microparticle fabrication contribute to breakthroughs in other industries

Advancements in microparticle fabrication through innovative methods like 3D printing have the potential to catalyze breakthroughs across various industries. For instance, in the pharmaceutical sector, precise control over microparticle geometry enables targeted drug delivery systems that enhance therapeutic efficacy while reducing side effects. In electronics manufacturing, customized microcomponents produced through advanced fabrication techniques can improve device performance and miniaturization capabilities. Furthermore, advancements in microparticle fabrication could revolutionize fields such as biotechnology by enabling novel approaches for tissue engineering or creating advanced sensors for environmental monitoring applications.

0