betekintés - Computer hardware - # CMOS-Compatible Fabrication of High-Coherence Superconducting Qubits

Scaling Superconducting Qubit Fabrication to 300 mm Wafers Using Advanced CMOS Manufacturing Techniques

Alapfogalmak

Demonstration of manufacturing high-coherence superconducting transmon qubits using advanced industrial 300 mm CMOS fabrication processes, enabling scalable quantum computing.

Kivonat

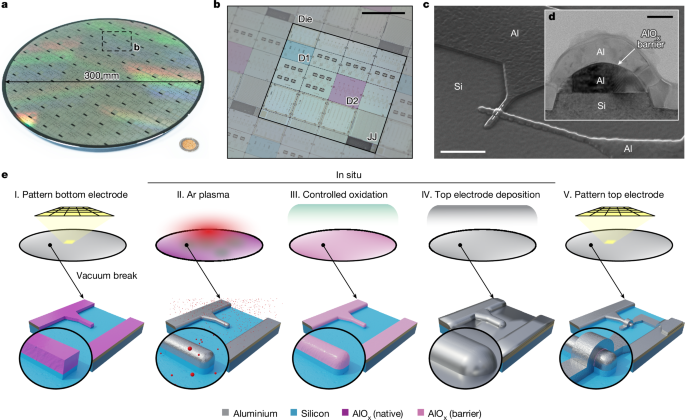

The article presents a breakthrough in the fabrication of superconducting qubits, the key building blocks of quantum computers. The researchers have successfully demonstrated the manufacturing of high-coherence transmon qubits using advanced 300 mm complementary metal-oxide-semiconductor (CMOS) fabrication processes typically used in the semiconductor industry.

The key highlights are:

- Superconducting transmon qubits were fabricated in a 300 mm CMOS pilot line using only optical lithography and reactive-ion etching, without the need for specialized techniques like metal lift-off, angled evaporation, and electron-beam writing.

- The resulting qubits exhibited relaxation and coherence times exceeding 100 μs, on par with conventional laboratory-style fabrication methods.

- Large-scale statistics across the wafer showed consistent performance, yield, and stability, validating the scalability of this approach.

- This industry-scale fabrication process offers the potential for further upscaling through 3D integration and process optimization, marking a significant step towards the realization of practical quantum computers.

Összefoglaló testreszabása

Átírás mesterséges intelligenciával

Hivatkozások generálása

Forrás fordítása

Egy másik nyelvre

Gondolattérkép létrehozása

a forrásanyagból

Forrás megtekintése

www.nature.com

Advanced CMOS manufacturing of superconducting qubits on 300 mm wafers - Nature

Statisztikák

The relaxation and coherence times of the fabricated superconducting qubits exceeded 100 μs.

Idézetek

"The presented industry-scale fabrication process, which uses only optical lithography and reactive-ion etching, has a performance and yield in line with conventional laboratory-style techniques utilizing metal lift-off, angled evaporation and electron-beam writing."

"This result marks the advent of an alternative and new, large-scale, truly CMOS-compatible fabrication method for superconducting quantum computing processors."

Főbb Kivonatok

by J. Van Damme... : www.nature.com 09-18-2024

https://www.nature.com/articles/s41586-024-07941-9

Mélyebb kérdések

How can the presented CMOS-compatible fabrication process be further optimized to improve the coherence and performance of superconducting qubits?

The CMOS-compatible fabrication process for superconducting qubits can be further optimized through several avenues. First, enhancing material quality is crucial; using high-purity superconducting materials and optimizing deposition techniques can reduce defects and impurities that negatively impact coherence times. Additionally, refining the lithography process to achieve finer feature sizes and improved pattern fidelity can lead to better qubit designs with reduced cross-talk and improved isolation between qubits.

Another optimization strategy involves the implementation of advanced surface treatments and passivation techniques to minimize surface losses, which are a significant source of decoherence in superconducting qubits. Furthermore, exploring alternative fabrication methods, such as atomic layer deposition (ALD) for thin films, could provide better control over material properties at the nanoscale. Finally, integrating feedback from real-time coherence measurements into the fabrication process could allow for adaptive tuning of parameters, leading to continuous improvement in qubit performance.

What are the potential challenges and limitations in scaling this approach to even larger wafer sizes or higher qubit densities?

Scaling the CMOS-compatible fabrication process to larger wafer sizes or higher qubit densities presents several challenges. One major limitation is the uniformity of the fabrication process across larger areas; maintaining consistent material properties and fabrication tolerances becomes increasingly difficult as wafer size increases. Variability in qubit performance due to local defects or variations in the fabrication environment can lead to reduced yield and coherence times.

Additionally, as qubit density increases, issues related to thermal management and cross-talk between qubits become more pronounced. Effective cooling solutions must be developed to ensure that qubits operate at optimal temperatures without interference from neighboring qubits. Moreover, the complexity of the control circuitry required to manage a higher number of qubits can introduce additional challenges in terms of signal integrity and routing.

Finally, the integration of three-dimensional architectures, while promising for increasing qubit density, requires careful consideration of the interactions between layers and the potential for increased fabrication complexity. Addressing these challenges will be essential for the successful scaling of superconducting qubit technology.

What other quantum computing hardware technologies could benefit from the adoption of advanced industrial fabrication techniques, and how might this impact the development of practical quantum computers?

Other quantum computing hardware technologies that could benefit from advanced industrial fabrication techniques include trapped ion systems, photonic quantum computing, and topological qubits. For trapped ion systems, the precision and scalability of industrial fabrication could enhance the design of ion traps and optical components, leading to improved qubit control and reduced error rates.

In photonic quantum computing, the ability to fabricate integrated photonic circuits using CMOS-compatible methods could enable the development of more compact and efficient quantum communication systems. This would facilitate the creation of scalable quantum networks, essential for practical quantum computing applications.

Topological qubits, which rely on exotic materials and complex geometries, could also see improvements in fabrication consistency and yield through industrial techniques. This could accelerate the realization of fault-tolerant quantum computing architectures.

Overall, the adoption of advanced industrial fabrication techniques across various quantum technologies could significantly impact the development of practical quantum computers by enhancing scalability, reducing costs, and improving performance reliability, ultimately bringing us closer to realizing the full potential of quantum computing.

0