Innovative Ti-Ni Strain Glass Alloy Exhibits Exceptional Strength, Flexibility, and Temperature Stability

Основные понятия

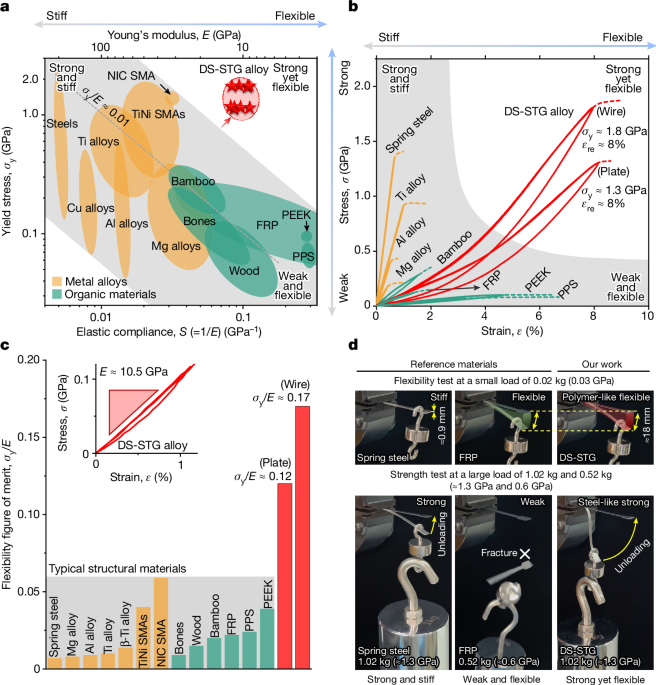

A novel Ti-Ni strain glass alloy demonstrates an exceptional combination of ultrahigh yield strength, ultralow elastic modulus, and super-large rubber-like elastic strain, making it a promising candidate for futuristic technologies.

Аннотация

The content describes the development of a novel Ti-Ni strain glass alloy that exhibits an exceptional combination of material properties. Key highlights:

- The alloy achieves an ultrahigh yield strength of around 1.8 GPa and an ultralow elastic modulus of 10.5 GPa, along with a super-large rubber-like elastic strain of approximately 8%.

- This unique combination of high strength and flexibility is achieved through a specialized three-step thermomechanical treatment that creates a "dual-seed strain glass" microstructure.

- In situ X-ray diffractometry reveals that the polymer-like deformation behavior originates from a reversible transition between the strain glass matrix and R and B19' martensite "seeds" during loading and unloading.

- The alloy maintains these exceptional properties over a wide temperature range of -80°C to +80°C and demonstrates excellent fatigue resistance at high strain.

- The simple and scalable fabrication process makes this alloy a promising candidate for various futuristic applications, such as morphing aerospace vehicles, artificial muscles, and artificial organs.

Настроить сводку

Переписать с помощью ИИ

Создать цитаты

Перевести источник

На другой язык

Создать интеллект-карту

из исходного контента

Перейти к источнику

www.nature.com

A polymer-like ultrahigh-strength metal alloy - Nature

Статистика

The alloy exhibits an ultrahigh yield strength of σy ≈ 1.8 GPa and an ultralow elastic modulus of E ≈ 10.5 GPa.

It can achieve a super-large rubber-like elastic strain of approximately 8%.

Цитаты

"As a result, it possesses a high flexibility figure of merit of σy/E ≈ 0.17 compared with existing structural materials."

"This exotic alloy with the potential for mass producibility may open a new horizon for many futuristic technologies, such as morphing aerospace vehicles, superman-type artificial muscles and artificial organs."

Ключевые выводы из

by Zhizhi Xu,Yu... в www.nature.com 09-04-2024

https://www.nature.com/articles/s41586-024-07900-4

Дополнительные вопросы

What are the specific applications and design considerations for this alloy in the context of morphing aerospace vehicles, artificial muscles, and artificial organs?

The Ti–50.8 at.% Ni strain glass alloy presents a remarkable combination of ultrahigh yield strength and polymer-like flexibility, making it an ideal candidate for several advanced applications.

Morphing Aerospace Vehicles: In aerospace engineering, the ability to adapt the shape of an aircraft in response to changing flight conditions is crucial for optimizing performance and fuel efficiency. The alloy's high flexibility figure of merit (σy/E ≈ 0.17) allows for significant deformation without compromising structural integrity. Design considerations include ensuring that the alloy can withstand extreme temperatures and fatigue during repeated morphing cycles. The unique dual-seed strain glass microstructure enables the alloy to undergo reversible phase transformations, which can be harnessed to create lightweight, adaptable wing structures that enhance aerodynamic efficiency.

Artificial Muscles: The super-large rubber-like elastic strain of approximately 8% makes this alloy suitable for artificial muscle applications, where high strength and flexibility are essential. In designing artificial muscles, engineers must consider the alloy's response to cyclic loading and its ability to maintain performance over time. The strain glass behavior allows for efficient energy storage and release, mimicking natural muscle contractions. Additionally, the alloy's temperature stability ensures functionality in various environments, which is critical for applications in robotics and prosthetics.

Artificial Organs: For artificial organs, particularly those that require dynamic movement or flexibility, such as heart valves or vascular grafts, the alloy's properties can be leveraged to create biocompatible devices that mimic the mechanical behavior of natural tissues. Design considerations include ensuring that the alloy can be safely integrated with biological systems and that it maintains its mechanical properties under physiological conditions. The alloy's excellent fatigue resistance is particularly advantageous in applications where long-term durability is required.

How does the microstructural evolution and phase transformations in this alloy compare to other high-strength, flexible metal alloys, and what are the implications for further optimization?

The microstructural evolution of the Ti–50.8 at.% Ni strain glass alloy is characterized by a unique dual-seed strain glass microstructure, which consists of a strain glass matrix with aligned R and B19′ martensite seeds. This contrasts with traditional high-strength metal alloys, which often rely on uniform grain structures or precipitate strengthening mechanisms.

Phase Transformations: The alloy exhibits a nucleation-free reversible transition between strain glass and martensite phases during loading and unloading, which is a distinct feature compared to other alloys that may require nucleation events for phase changes. This behavior allows for greater flexibility and energy absorption, making the alloy more adaptable to dynamic loading conditions.

Implications for Optimization: Understanding the microstructural evolution and phase transformations opens avenues for further optimization of the alloy. By tailoring the composition and processing parameters, such as heat treatment and mechanical deformation, it may be possible to enhance specific properties like strength, flexibility, and fatigue resistance. For instance, adjusting the alloying elements or the thermomechanical treatment could lead to improved performance in targeted applications, such as higher elastic strains or better thermal stability.

What other unique material properties or functionalities could be achieved by tailoring the composition and processing of this strain glass alloy system?

Tailoring the composition and processing of the Ti–50.8 at.% Ni strain glass alloy system can lead to the development of several unique material properties and functionalities:

Enhanced Damping Properties: By modifying the alloy's microstructure, it may be possible to enhance its damping capabilities, which would be beneficial in applications requiring vibration absorption, such as in aerospace structures or automotive components.

Shape Memory Effects: Adjusting the composition could induce shape memory effects, allowing the alloy to return to a predetermined shape after deformation. This property is particularly useful in applications like self-healing materials or deployable structures in aerospace.

Corrosion Resistance: Incorporating additional alloying elements could improve the corrosion resistance of the strain glass alloy, making it suitable for use in harsh environments, such as marine or chemical applications.

Biocompatibility: For applications in biomedical fields, optimizing the alloy for biocompatibility could lead to the development of implants or devices that integrate seamlessly with biological tissues, reducing the risk of rejection.

Thermal Conductivity: Tailoring the alloy's composition could also enhance its thermal conductivity, which would be advantageous in applications requiring efficient heat dissipation, such as in electronic devices or thermal management systems.

By exploring these avenues, researchers can unlock the full potential of the strain glass alloy system, paving the way for innovative applications across various industries.

0