Flex-RV: A Bendable 32-bit RISC-V Microprocessor with Integrated Machine Learning Accelerator

แนวคิดหลัก

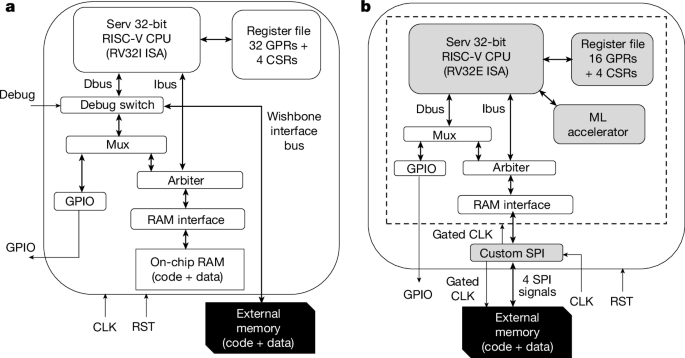

Flex-RV, a 32-bit RISC-V microprocessor fabricated with indium gallium zinc oxide thin-film transistors on a flexible polyimide substrate, enables an ultralow-cost bendable microprocessor with integrated machine learning hardware accelerator.

บทคัดย่อ

The content presents Flex-RV, a novel 32-bit microprocessor based on the open RISC-V instruction set. Key highlights:

- Flex-RV is fabricated using indium gallium zinc oxide thin-film transistors on a flexible polyimide substrate, enabling a bendable microprocessor design.

- It integrates a programmable machine learning (ML) hardware accelerator within the microprocessor, extending the RISC-V instruction set to support ML workloads.

- Flex-RV is implemented, fabricated, and demonstrated to operate at 60 kHz while consuming less than 6 mW of power.

- The functionality of Flex-RV is validated when assembled onto a flexible printed circuit board, with no more than 4.3% performance variation under flat and tight bending conditions.

- Flex-RV pioneers the development of sub-dollar open-standard non-silicon 32-bit microprocessors, democratizing access to computing and unlocking emerging applications in wearables, healthcare devices, and smart packaging.

ปรับแต่งบทสรุป

เขียนใหม่ด้วย AI

สร้างการอ้างอิง

แปลแหล่งที่มา

เป็นภาษาอื่น

สร้าง MindMap

จากเนื้อหาต้นฉบับ

ไปยังแหล่งที่มา

www.nature.com

Bendable non-silicon RISC-V microprocessor - Nature

สถิติ

Flex-RV operates at 60 kHz and consumes less than 6 mW of power.

Flex-RV demonstrates no more than 4.3% performance variation under flat and tight bending conditions.

คำพูด

"Flex-RV pioneers an era of sub-dollar open standard non-silicon 32-bit microprocessors and will democratize access to computing and unlock emerging applications in wearables, healthcare devices and smart packaging."

ข้อมูลเชิงลึกที่สำคัญจาก

by Emre Ozer,Je... ที่ www.nature.com 09-25-2024

https://www.nature.com/articles/s41586-024-07976-y

สอบถามเพิ่มเติม

How can the integration of the ML hardware accelerator in Flex-RV be further optimized to improve its performance and energy efficiency for specific ML workloads?

To optimize the integration of the machine learning (ML) hardware accelerator within the Flex-RV microprocessor, several strategies can be employed. First, tailoring the architecture of the ML accelerator to specific workloads can significantly enhance performance. This could involve implementing specialized processing units designed for common ML tasks, such as convolutional neural networks (CNNs) or recurrent neural networks (RNNs), which would allow for more efficient data handling and computation.

Additionally, optimizing the memory hierarchy is crucial. By incorporating local memory caches that are specifically designed for ML data patterns, the Flex-RV can reduce latency and energy consumption associated with data access. Techniques such as quantization, which reduces the precision of the data used in ML models, can also be applied to decrease the computational load and power requirements without significantly impacting accuracy.

Furthermore, dynamic voltage and frequency scaling (DVFS) can be implemented to adjust the power consumption based on the workload demands, allowing the microprocessor to operate at lower power levels during less intensive tasks. Finally, leveraging software optimizations, such as compiler techniques that can better schedule ML operations and reduce overhead, will also contribute to improved performance and energy efficiency.

What are the potential challenges and limitations in scaling the Flex-RV design to higher performance levels while maintaining its flexibility and low-cost characteristics?

Scaling the Flex-RV design to achieve higher performance levels presents several challenges and limitations. One primary concern is the trade-off between performance and the inherent flexibility of the substrate. As performance demands increase, the complexity of the microprocessor architecture may necessitate the use of more rigid materials or advanced fabrication techniques that could compromise the bendability and low-cost attributes of the device.

Thermal management is another significant challenge. Higher performance typically leads to increased heat generation, which can affect the reliability and longevity of flexible electronics. Developing effective thermal dissipation methods that do not interfere with the flexible design will be crucial.

Moreover, the integration of additional components or more complex circuitry to enhance performance could lead to increased manufacturing costs, counteracting the goal of maintaining a sub-dollar price point. Ensuring that the production processes remain cost-effective while scaling up the design will require innovative approaches in materials and manufacturing techniques.

Lastly, achieving higher performance levels may necessitate more sophisticated power management solutions, which could complicate the design and increase the overall power consumption, thus impacting the energy efficiency that is a hallmark of the Flex-RV microprocessor.

What other emerging applications beyond wearables, healthcare devices, and smart packaging could benefit from the unique capabilities of a bendable microprocessor like Flex-RV, and how could the design be adapted to address those use cases?

Beyond wearables, healthcare devices, and smart packaging, several emerging applications could benefit from the unique capabilities of a bendable microprocessor like Flex-RV. One promising area is the Internet of Things (IoT), where flexible sensors and devices can be integrated into various environments, such as smart homes or industrial settings. The Flex-RV could be adapted to support low-power, always-on sensing applications, enabling real-time data collection and processing in a compact form factor.

Another potential application is in robotics, particularly in soft robotics, where flexibility is essential for movement and interaction with the environment. The Flex-RV could be designed to control actuators and process sensory data in soft robotic systems, enhancing their adaptability and functionality.

Additionally, the automotive industry could leverage bendable microprocessors for applications in flexible displays or smart surfaces within vehicles. The design could be adapted to include enhanced graphics processing capabilities and connectivity features to support advanced driver-assistance systems (ADAS) and infotainment systems.

To address these use cases, the Flex-RV design could incorporate modular components that allow for easy integration with various sensors and actuators, as well as enhanced communication protocols to facilitate connectivity in IoT applications. Furthermore, optimizing the microprocessor for specific tasks, such as real-time data processing or low-latency communication, would make it more versatile across different industries.

0