Glassy Polymers Transformed into Tough, Stretchable Gels through Ionic Liquid Swelling

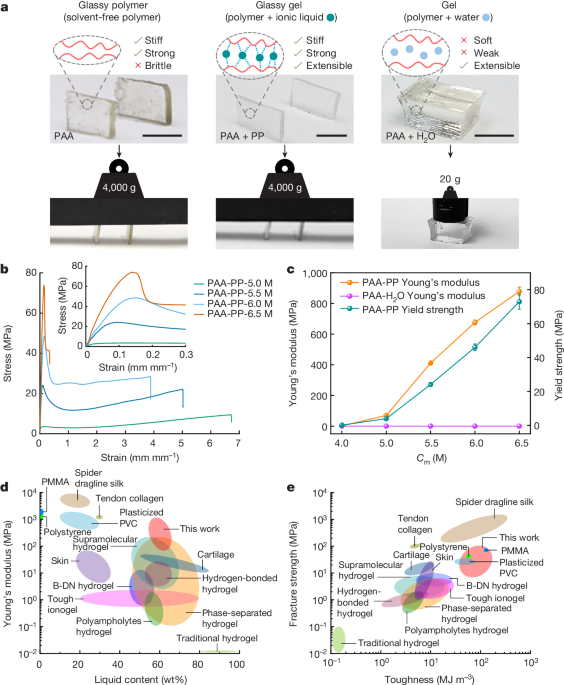

The content describes a novel class of materials called "glassy gels" that combine the desirable properties of both glasses and gels. Typically, glassy polymers are stiff and strong but have limited extensibility. Swelling these polymers with solvents can make them soft and weak gels with enhanced extensibility.

The key innovation presented here is the use of ionic liquids to swell and toughen glassy polymers. The ionic liquids increase the free volume between polymer chains, enhancing extensibility, while also forming strong non-covalent crosslinks that render the material stiff, tough, and homogeneous (no phase separation).

Despite being over 54% liquid, these glassy gels exhibit impressive mechanical properties - high fracture strength (42 MPa), toughness (110 MJ/m^3), yield strength (73 MPa), and Young's modulus (1 GPa), comparable to thermoplastics like polyethylene. Crucially, they can be deformed up to 670% strain with full and rapid recovery on heating, unlike typical thermoplastics.

These transparent glassy gels are formed in a single-step polymerization process and also exhibit useful adhesive, self-healing, and shape-memory properties.

Összefoglaló testreszabása

Átírás mesterséges intelligenciával

Hivatkozások generálása

Forrás fordítása

Egy másik nyelvre

Gondolattérkép létrehozása

a forrásanyagból

Forrás megtekintése

www.nature.com

Glassy gels toughened by solvent - Nature

Főbb Kivonatok

by Meixiang Wan... : www.nature.com 06-19-2024

https://www.nature.com/articles/s41586-024-07564-0

Mélyebb kérdések