Engineered Yeast Strains Produce Potent Plant-Derived Vaccine Adjuvant for Improved Immunogenicity

Core Concepts

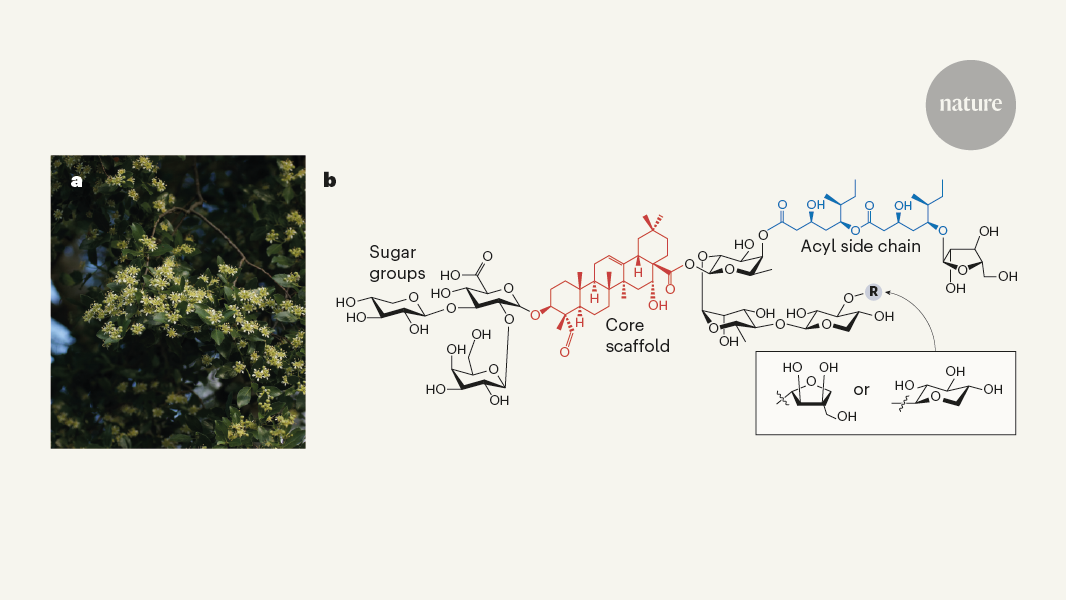

Engineered yeast strains can be used to efficiently produce a potent plant-derived vaccine adjuvant, overcoming the challenges of low yields and ecosystem damage associated with direct plant extraction.

Abstract

The article discusses the potential of using engineered yeast strains to produce a plant-derived vaccine adjuvant, which can enhance the efficacy of vaccines by boosting the immune system's response.

Plants have long been a source of various medicinal compounds, including vaccine adjuvants - substances that increase the potency of vaccines. However, directly extracting and isolating these plant-derived molecules can be challenging, often resulting in low yields and potential damage to ecosystems. Chemically synthesizing these complex plant molecules is also difficult and expensive.

The researchers, Liu et al., have provided a promising solution to this problem by engineering strains of the common yeast Saccharomyces cerevisiae to produce a potent plant-derived vaccine adjuvant. Yeast is an easy-to-grow microorganism, making it a more efficient and scalable platform for the production of these valuable plant-derived compounds.

The key highlights of the article are:

Plants are a rich source of medicinal compounds, including vaccine adjuvants that enhance the immune response to vaccines.

Directly extracting and isolating plant-derived molecules can be problematic, leading to low yields and ecosystem damage.

Chemical synthesis of complex plant molecules is challenging and costly.

The researchers engineered yeast strains to produce a potent plant-derived vaccine adjuvant, overcoming the limitations of direct plant extraction.

Yeast is an easy-to-grow microorganism, making it a more efficient and scalable platform for the production of valuable plant-derived compounds.

Vaccine-enhancing plant extract could be mass produced in yeast

Stats

Plants have long been a source of medicines, including painkillers, anti-cancer drugs, treatments for neurological disorders and even vaccine adjuvants.

Extracting and isolating plant-derived molecules directly from plants can result in low yields and damage to ecosystems.

Synthesizing complex plant molecules chemically is difficult and often expensive.

Quotes

"Plants have long been a source of medicines, including painkillers, anti-cancer drugs, treatments for neurological disorders and even vaccine adjuvants1 — compounds that increase the efficacy of vaccines by enhancing the immune system's response to a molecule that is recognized as an antigen."

"However, obtaining plant-derived molecules is frequently challenging. Extracting and isolating them directly from plants can result in low yields and damage to ecosystems, and synthesizing complex plant molecules chemically is difficult and often expensive2."

Key Insights Distilled From

by Ryan Nett at www.nature.com 05-08-2024

https://www.nature.com/articles/d41586-024-01210-5

Deeper Inquiries

What other plant-derived compounds could be produced more efficiently using engineered yeast strains?

With the success of synthesizing a potent plant-derived vaccine adjuvant in engineered yeast strains, the possibilities for producing other plant-derived compounds are vast. Compounds such as flavonoids, terpenoids, alkaloids, and polyphenols, which have various medicinal properties, could be efficiently produced using engineered yeast strains. These compounds are found in plants and have been used in traditional medicine for their therapeutic effects. By leveraging the metabolic pathways of yeast and introducing the necessary enzymes, it is feasible to biosynthesize these plant-derived compounds in yeast at a larger scale and with higher purity compared to traditional extraction methods.

What are the potential limitations or challenges in scaling up the production of plant-derived vaccine adjuvants in yeast?

While the use of engineered yeast strains for producing plant-derived vaccine adjuvants offers numerous advantages, there are also potential limitations and challenges in scaling up production. One major challenge is optimizing the fermentation process to achieve high yields of the desired compound consistently. This involves fine-tuning the growth conditions, nutrient supply, and metabolic pathways of the yeast to maximize production efficiency. Additionally, downstream processing steps, such as purification and extraction of the adjuvants from yeast cells, can be complex and costly, especially when dealing with large volumes of biomass. Furthermore, regulatory hurdles and safety concerns related to genetically modified organisms (GMOs) may pose challenges in the commercialization and widespread adoption of yeast-produced vaccine adjuvants.

How could the use of engineered yeast-produced vaccine adjuvants impact the development and distribution of more effective vaccines, particularly in resource-limited settings?

The use of engineered yeast-produced vaccine adjuvants has the potential to revolutionize the development and distribution of vaccines, especially in resource-limited settings. By harnessing the scalability and cost-effectiveness of yeast fermentation, vaccine adjuvants can be produced in large quantities at a lower cost compared to traditional methods. This could lead to the development of more affordable vaccines with enhanced efficacy, as the adjuvants play a crucial role in boosting the immune response to vaccines. In resource-limited settings where access to vaccines is limited, the availability of cost-effective and potent adjuvants produced in yeast could facilitate the production of vaccines against a wide range of diseases. This, in turn, could help improve vaccination coverage and control the spread of infectious diseases in vulnerable populations.

0