Highly Regioselective Rhodium-Zeolite Catalyst for Propene Hydroformylation to n-Butanal

Core Concepts

Encapsulation of rhodium species within a MEL zeolite framework enables highly regioselective hydroformylation of propene to n-butanal, surpassing the performance of existing heterogeneous and homogeneous catalysts.

Abstract

The content discusses the development of a highly regioselective rhodium-zeolite catalyst for the hydroformylation of propene to produce n-butanal, an important industrial chemical.

Key highlights:

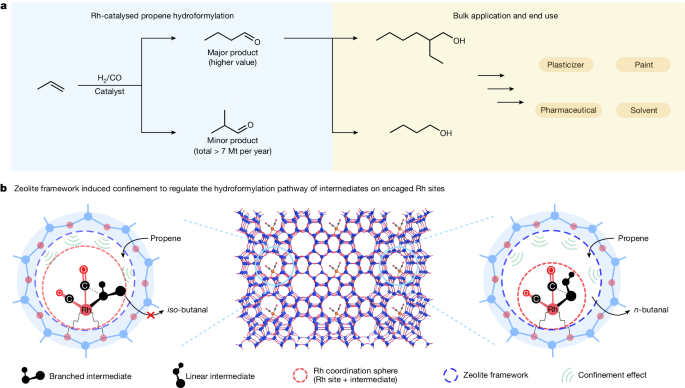

Hydroformylation is an important industrial process for producing aldehydes from alkenes. Regioselective production of n-butanal from propene is particularly valuable.

Supported rhodium catalysts are commonly used but often have limited regioselectivity towards n-butanal due to the flexible and unconstrained nature of the rhodium hydride dicarbonyl centers.

The authors show that encapsulating rhodium species comprising Rh(I)-gem-dicarbonyl centers within a MEL zeolite framework can overcome this limitation.

The optimized catalyst exhibits over 99% regioselectivity to n-butanal and over 99% selectivity to aldehydes, with a high turnover frequency of 6,500 h^-1.

The zeolite framework acts as a scaffold to steer the reaction pathway of the intermediates towards exclusive formation of n-butanal.

This represents a significant advancement in heterogeneous hydroformylation catalysts, surpassing the performance of existing homogeneous and heterogeneous catalysts.

Regioselective hydroformylation of propene catalysed by rhodium-zeolite - Nature

Stats

The catalyst exhibits more than 99% regioselectivity to n-butanal and more than 99% selectivity to aldehydes at a product formation turnover frequency (TOF) of 6,500 h−1.

Quotes

"Here we show that proper encapsulation of Rh species comprising Rh(I)-gem-dicarbonyl centres within a MEL zeolite framework allows the breaking of the above model."

"Our comprehensive studies show that the zeolite framework can act as a scaffold to steer the reaction pathway of the intermediates confined in the space between the zeolite framework and Rh centres towards the exclusive formation of n-butanal."

Key Insights Distilled From

by Xiangjie Zha... at www.nature.com 04-24-2024

https://www.nature.com/articles/s41586-024-07342-y

Deeper Inquiries

What are the potential industrial applications and economic implications of this highly regioselective rhodium-zeolite catalyst for propene hydroformylation?

The highly regioselective rhodium-zeolite catalyst for propene hydroformylation offers significant industrial applications and economic implications. Firstly, the exclusive production of n-butanal with more than 99% regioselectivity and selectivity to aldehydes at a high turnover frequency of 6,500 h−1 opens up avenues for efficient and cost-effective manufacturing of n-butanal. This compound has diverse industrial applications, including its use in the production of various necessities in human daily life. The high regioselectivity of the catalyst ensures that the desired product is obtained with minimal by-products, reducing the need for costly purification processes. Additionally, the catalyst's performance surpasses that of all heterogeneous and most homogeneous catalysts developed to date, indicating its potential for large-scale industrial adoption. The catalyst's recyclability, ease of separation, and adaptability for continuous-flow processes further enhance its economic viability by reducing operational costs and increasing overall efficiency in the hydroformylation process.

How does the catalyst design and performance compare to other recent advances in heterogeneous hydroformylation catalysts?

The design and performance of the rhodium-zeolite catalyst for propene hydroformylation represent a significant advancement compared to other recent heterogeneous hydroformylation catalysts. Unlike traditional supported Rh catalysts that exhibit limited regioselectivity due to rotationally flexible and sterically unconstrained Rh hydride dicarbonyl centers, the encapsulation of Rh species within a MEL zeolite framework in this catalyst breaks this model. The optimized catalyst achieves exceptional regioselectivity to n-butanal and selectivity to aldehydes, surpassing the performance of all heterogeneous and most homogeneous catalysts developed thus far. The zeolite framework acts as a scaffold to direct the reaction pathway of intermediates towards the exclusive formation of n-butanal, showcasing a novel approach to enhancing regioselectivity in hydroformylation reactions. This superior performance in terms of regioselectivity, selectivity, and turnover frequency positions the rhodium-zeolite catalyst as a frontrunner in the field of heterogeneous hydroformylation catalysts.

What insights from this work could be applied to develop highly selective catalysts for other industrially relevant reactions?

The insights gained from the development of the highly regioselective rhodium-zeolite catalyst for propene hydroformylation can be instrumental in the design of highly selective catalysts for other industrially relevant reactions. One key takeaway is the importance of proper encapsulation of catalytic species within a suitable framework, such as a zeolite, to control the reaction pathway and enhance selectivity. By confining intermediates within the space between the framework and catalytic centers, it is possible to steer the reaction towards the desired products with high selectivity. This approach can be extrapolated to other catalytic systems where regioselectivity and product selectivity are crucial, offering a new paradigm for developing efficient and selective catalysts for a wide range of industrial reactions. Additionally, the success of this catalyst underscores the significance of understanding the interaction between the catalyst, framework, and reaction intermediates, providing a blueprint for the rational design of selective catalysts tailored to specific industrial applications.

0