insight - Computational Complexity - # Nano-Achiral Complex Composites for Polarization-Sensitive Optics

Engineered Nano-Achiral Composites Enabling Extreme Polarization Optics for High-Temperature Applications

Core Concepts

Multilayer nanocomposites from 2D nanomaterials with complex textured surfaces can strongly and controllably rotate light polarization, despite being nano-achiral and partially disordered, enabling high-performance polarization optics for extreme conditions.

Abstract

The content discusses the development of composite materials from 2D nanomaterials that exhibit unique polarization-rotating properties, despite their inherent nano-achiral and partially disordered nature. Key highlights:

Composites from 2D nanomaterials like molybdenum sulfide (MoS2), MXene, and graphene oxide (GO) show high electrical, thermal, and mechanical properties, making them promising for polarization-sensitive optics in extreme conditions.

The rigid nanoplatelets in these composites have randomized achiral shapes, which typically scramble the circular polarization of photons with comparable wavelengths.

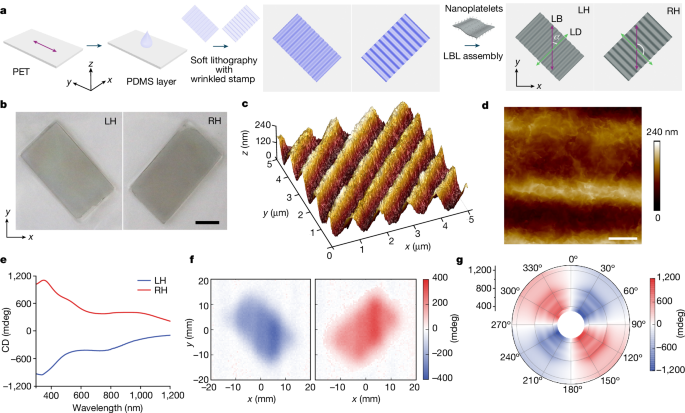

However, the authors demonstrate that multilayer nanocomposites with complex textured surfaces (e.g., wrinkles, grooves, or ridges) can strongly and controllably rotate light polarization.

This polarization-rotating effect originates from the diagonal patterns in the nanocomposite structure, which create an angular offset between the axes of linear birefringence (LB) and linear dichroism (LD).

Stratification of the layer-by-layer (LBL) assembled nanocomposites allows for precise engineering of the polarization-active materials, achieving an optical asymmetry g-factor of 1.0, which is about 500 times higher than typical nanomaterials.

The high thermal resilience of these composite optics enables operating temperatures up to 250°C, enabling imaging of hot emitters in the near-infrared (NIR) spectrum.

Combining the LBL-engineered nanocomposites with achiral dyes results in anisotropic factors for circularly polarized emission approaching the theoretical limit.

The authors demonstrate the generality of this approach by fabricating nanocomposite polarizers from various 2D nanomaterials using different manufacturing methods, and suggest the potential for computational design and additive engineering of a large family of LBL optical nanocomponents.

Nano-achiral complex composites for extreme polarization optics - Nature

Stats

The nanocomposite optics can operate at temperatures up to 250°C.

The optical asymmetry g-factor of the nanocomposites is 1.0, which is about 500 times higher than typical nanomaterials.

Quotes

"Stratification of the layer-by-layer (LBL) assembled nanocomposites affords precise engineering of the polarization-active materials from imprecise nanoplatelets with an optical asymmetry g-factor of 1.0, exceeding those of typical nanomaterials by about 500 times."

"High thermal resilience of the composite optics enables operating temperature as high as 250 °C and imaging of hot emitters in the near-infrared (NIR) part of the spectrum."

Key Insights Distilled From

by Jun Lu,Wenbi... at www.nature.com 05-29-2024

https://www.nature.com/articles/s41586-024-07455-4

Deeper Inquiries

How can the computational design and additive engineering of LBL optical nanocomponents be leveraged to create novel polarization-sensitive devices for specific applications?

The computational design and additive engineering of Layer-by-Layer (LBL) optical nanocomponents offer a promising avenue for creating innovative polarization-sensitive devices tailored for specific applications. By leveraging computational tools, researchers can precisely design the nanostructures of these optical components to exhibit desired polarization properties. Additive manufacturing techniques enable the fabrication of complex nanocomposite structures with high precision and repeatability, allowing for the customization of polarization effects based on the intended application requirements. This approach opens up possibilities for developing advanced polarizers, waveplates, and other optical components that can manipulate light polarization in unique ways, catering to diverse fields such as telecommunications, imaging, and sensing.

What are the potential limitations or challenges in scaling up the production of these high-performance nanocomposite polarization optics for real-world use?

While high-performance nanocomposite polarization optics show great promise, scaling up their production for real-world applications poses several challenges. One limitation is the scalability of the manufacturing processes used to create these nanocomposites. Achieving uniformity and consistency in large-scale production can be complex, especially when dealing with intricate nanostructures that require precise control over their assembly. Additionally, the cost-effectiveness of producing these advanced nanocomposites in bulk quantities needs to be addressed to make them commercially viable. Ensuring the durability and reliability of the optics under varying environmental conditions is another crucial factor to consider when scaling up production. Furthermore, regulatory compliance and safety standards must be met to facilitate the widespread adoption of these nanocomposite polarization optics in practical applications.

What other unique properties or functionalities could be achieved by combining the textured nanocomposite structures with different types of 2D nanomaterials or doping agents?

Combining textured nanocomposite structures with various types of 2D nanomaterials or doping agents opens up a realm of possibilities for achieving novel properties and functionalities beyond polarization manipulation. By incorporating different nanomaterials, such as molybdenum sulfide (MoS2), MXene, and graphene oxide (GO), into the nanocomposite structures, researchers can tailor the optical, electrical, and mechanical characteristics of the materials. This opens avenues for developing multifunctional nanocomposites with capabilities like enhanced light absorption, tunable electrical conductivity, and improved mechanical strength. Doping agents can further modify the properties of the nanocomposites, enabling functionalities such as photoresponse, chemical sensing, or catalytic activity. The synergistic effects of combining textured nanocomposite structures with diverse nanomaterials or dopants offer a rich platform for creating advanced materials with a wide range of applications in photonics, electronics, and energy storage.

0