insight - Materials Science - # Bevel-Edge Epitaxy for Rhombohedral Boron Nitride Single Crystal Growth

Bevel-Edge Epitaxy Enables Large-Scale Growth of Ferroelectric Rhombohedral Boron Nitride Single Crystals

Core Concepts

Bevel-edge epitaxy on a vicinal nickel surface enables the growth of centimeter-sized, single-crystal rhombohedral boron nitride layers with precise interlayer ABC stacking, leading to robust and switchable ferroelectricity.

Abstract

The content discusses the growth of large-sized, single-crystal rhombohedral boron nitride (rBN) layers, which possess superior properties compared to hexagonal boron nitride, including optical nonlinearity and interfacial ferroelectricity. However, the preparation of such rBN layers has been challenging due to the need for precise control over the lattice orientation and interlayer stacking.

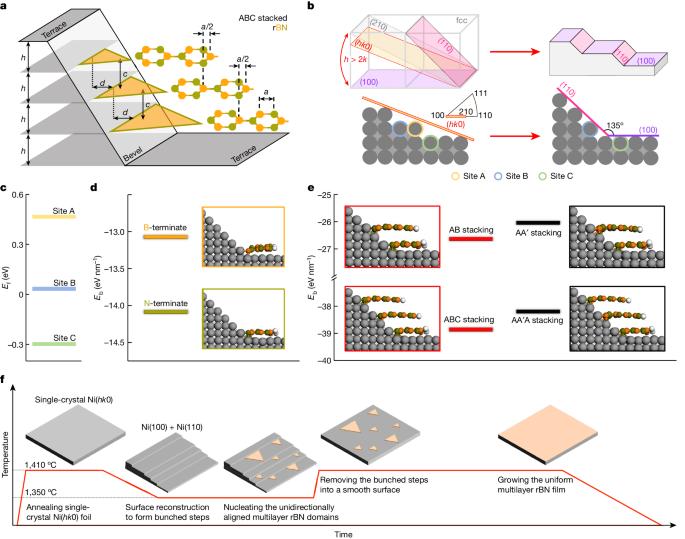

The authors report a novel approach using bevel-edge epitaxy on a vicinal nickel surface to address this challenge. The key insights are:

- The bevel-edge epitaxy simultaneously guides the consistent boron-nitrogen bond orientation in each BN layer and the rhombohedral stacking of BN layers via nucleation near the bevel facet.

- This method enables the growth of centimeter-sized, single-crystal rBN layers with exact interlayer ABC stacking on the vicinal nickel substrate.

- The as-grown rBN layers exhibit a pure rhombohedral phase and show robust, homogeneous, and switchable ferroelectricity with a high Curie temperature.

- This work provides an effective route for accurate stacking-controlled growth of single-crystal two-dimensional materials and lays the foundation for developing multifunctional devices based on stacked 2D materials.

Customize Summary

Rewrite with AI

Generate Citations

Translate Source

To Another Language

Generate MindMap

from source content

Visit Source

www.nature.com

Bevel-edge epitaxy of ferroelectric rhombohedral boron nitride single crystal - Nature

Stats

The as-grown rBN layers exhibit robust, homogeneous, and switchable ferroelectricity with a high Curie temperature.

Quotes

"Our work provides an effective route for accurate stacking-controlled growth of single-crystal two-dimensional layers and presents a foundation for applicable multifunctional devices based on stacked two-dimensional materials."

Key Insights Distilled From

by Li Wang,Jiaj... at www.nature.com 05-01-2024

https://www.nature.com/articles/s41586-024-07286-3

Deeper Inquiries

What are the potential applications of the large-scale, single-crystal rBN layers with robust ferroelectricity?

The large-scale, single-crystal rhombohedral boron nitride (rBN) layers with robust ferroelectricity hold significant potential for various applications in the field of electronics and optoelectronics. One key application is in the development of high-performance ferroelectric devices such as non-volatile memories, ferroelectric field-effect transistors, and sensors. The robust and switchable ferroelectric properties of rBN can enable the creation of energy-efficient and fast-operating memory devices. Additionally, the unique optical nonlinearity of rBN can be harnessed for applications in photonics, such as in the development of optical modulators and switches. The high thermal conductivity of rBN also makes it suitable for applications in thermal management systems, where efficient heat dissipation is crucial.

How can the bevel-edge epitaxy technique be extended to the growth of other 2D materials with specific stacking orders?

The bevel-edge epitaxy technique demonstrated in the context of rhombohedral boron nitride (rBN) can be extended to the growth of other two-dimensional (2D) materials with specific stacking orders by leveraging the principles of lattice matching and surface energy minimization. By carefully selecting the substrate material and orientation, as well as controlling the growth conditions, it is possible to induce the desired stacking order in the 2D material. The use of vicinal surfaces with specific step configurations, similar to the bunched step edges utilized in the growth of rBN, can guide the nucleation and growth of 2D materials with precise stacking arrangements. Additionally, by understanding the interfacial interactions and energetics between the substrate and the 2D material, researchers can tailor the growth process to achieve the desired stacking order in a controlled manner.

What are the underlying mechanisms that enable the precise control of the boron-nitrogen bond orientation and rhombohedral stacking during the bevel-edge epitaxy process?

The precise control of the boron-nitrogen bond orientation and rhombohedral stacking during the bevel-edge epitaxy process is facilitated by the unique surface morphology and growth dynamics induced by the vicinal nickel substrate with bunched step edges. The bunched step edges on the nickel surface provide preferential sites for nucleation, guiding the initial growth of the rhombohedral boron nitride (rBN) layers. The interaction between the substrate and the rBN layers influences the orientation of the boron-nitrogen bonds, ensuring alignment with the substrate lattice. Additionally, the specific step configurations on the substrate surface promote the rhombohedral stacking of the rBN layers by controlling the sliding vector at each interface. This results in the formation of centimeter-sized single-crystal rBN layers with exact interlayer ABC stacking. Overall, the bevel-edge epitaxy process enables the precise control of bond orientation and stacking through the tailored growth conditions and substrate morphology, leading to the realization of high-quality, single-crystal rBN layers with desirable properties.

0