insight - Molecular Mechanics Polymer Chemistry - # Force-Triggered Release of Molecular Cargo Using Rotaxane Actuators

Rotaxane Actuator Enables Efficient Force-Controlled Release of Multiple Small Molecules

Core Concepts

A rotaxane actuator can efficiently trigger the release of up to five cargo molecules per rotaxane, achieving high release efficiency through mechanical force application.

Abstract

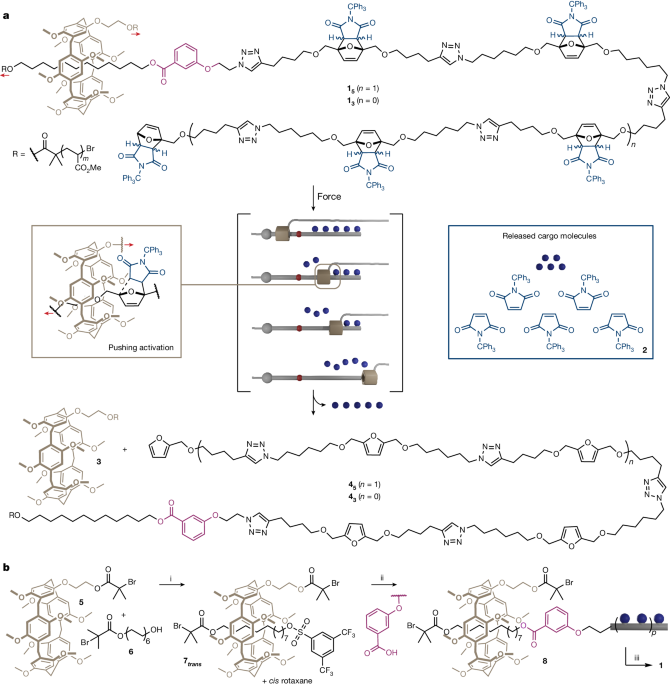

The article presents a novel approach to force-controlled release of small molecules using a rotaxane actuator. Rotaxanes are interlocked molecules where a macrocycle is trapped on a stoppered axle.

The key highlights are:

Existing polymer mechanochemistry techniques for releasing molecular cargo have limitations in the diversity and quantity of molecules released per stretching event.

The rotaxane actuator developed in this work can trigger the release of up to five cargo molecules per rotaxane, achieving release efficiencies of up to 71% in solution and 30% in bulk.

The authors demonstrate the release of three representative functional molecules - a drug, a fluorescent tag, and an organocatalyst - showcasing the versatility of the rotaxane platform.

This rotaxane actuator provides a promising approach for various force-controlled release applications in areas like drug delivery and materials science.

Force-controlled release of small molecules with a rotaxane actuator - Nature

Stats

Up to 5 cargo molecules released per rotaxane actuator

Release efficiency of up to 71% in solution and 30% in bulk

Quotes

"Force-controlled release of small molecules offers great promise for the delivery of drugs and the release of healing or reporting agents in a medical or materials context."

"This rotaxane actuator provides a versatile platform for various force-controlled release applications."

Key Insights Distilled From

by Lei Chen,Rob... at www.nature.com 04-10-2024

https://www.nature.com/articles/s41586-024-07154-0

Deeper Inquiries

How can the release efficiency of the rotaxane actuator be further improved, especially in bulk applications?

To enhance the release efficiency of the rotaxane actuator, particularly in bulk applications, several strategies can be implemented. One approach is to optimize the design of the rotaxane structure to ensure efficient cargo release. This can involve fine-tuning the interactions between the macrocycle and the stoppered axle to facilitate the controlled movement required for cargo release. Additionally, exploring different materials or modifications that can increase the mechanical responsiveness of the rotaxane actuator could lead to improved efficiency. Furthermore, incorporating advanced molecular engineering techniques to tailor the properties of the rotaxane components could enhance the overall performance of the system in releasing cargo molecules, especially in bulk scenarios.

What are the potential limitations or challenges in scaling up the production and use of these rotaxane-based release systems?

Scaling up the production and utilization of rotaxane-based release systems may face several limitations and challenges. One significant hurdle is the complexity and precision required in synthesizing rotaxane molecules on a large scale. The intricate interlocked structure of rotaxanes demands sophisticated synthetic methodologies, which can be challenging to replicate consistently in bulk production. Moreover, ensuring the reproducibility and quality control of rotaxane actuators at a larger scale poses logistical and technical difficulties. Additionally, the cost-effectiveness of manufacturing rotaxane-based systems in bulk quantities could be a limiting factor, as the synthesis and purification processes involved in producing these intricate molecules may be resource-intensive.

What other types of cargo molecules or functional payloads could be incorporated into the rotaxane design to expand its applications?

The versatility of rotaxane design allows for the incorporation of various cargo molecules and functional payloads to broaden its applications. Apart from the drug, fluorescent tag, and organocatalyst demonstrated in the context, other types of cargo molecules that could be integrated into the rotaxane structure include therapeutic agents for targeted drug delivery, imaging agents for diagnostic purposes, and chemical sensors for analytical applications. Functional payloads such as nanoparticles, enzymes, or even genetic material could also be attached to the rotaxane axle to enable diverse functionalities. By exploring the compatibility of different cargo molecules with the rotaxane actuator and tailoring the design to accommodate specific payloads, the range of applications for rotaxane-based release systems can be significantly expanded.

0