Efficient Cooling of Electronic Hot Spots with Well-Matched Vibrations

Core Concepts

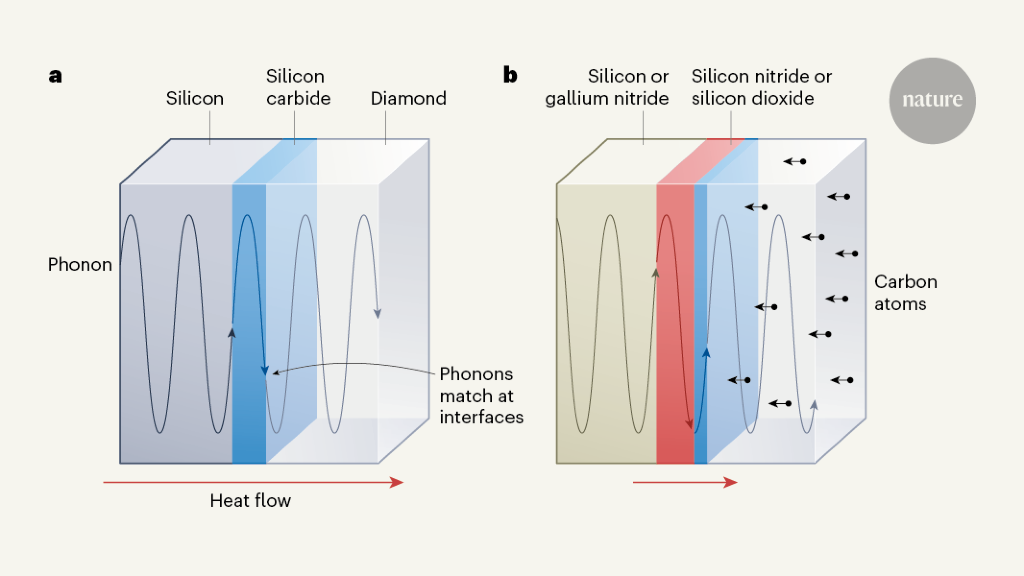

The author argues that managing heat dissipation in semiconductor transistors is crucial due to localized hotspots, proposing the use of ultrathin silicon carbide to reduce thermal boundary resistance significantly.

Abstract

Computer components are getting smaller and more powerful, making heat dissipation critical for semiconductor transistor design. Localized hotspots form due to confined electric fields, with synthetic diamond considered the best cooling strategy. However, resistance to heat flow can occur at the interface between diamond and common semiconductor materials like silicon and gallium nitride. Woo et al. have introduced a method using ultrathin silicon carbide to lower thermal boundary resistance significantly, as discussed at the International Electron Devices Meeting.

Well-matched vibrations cool electronic hot spots

Stats

The peak temperature of today’s transistors is mainly determined by localized hotspots.

Synthetic diamond is an efficient strategy for cooling hotspots but can lead to resistance at the interface with common semiconductor materials.

Ultrathin silicon carbide proposed by Woo et al. reduces thermal boundary resistance to record low values.

Quotes

Key Insights Distilled From

by Liwen Sang at www.nature.com 03-05-2024

https://www.nature.com/articles/d41586-024-00529-3

Deeper Inquiries

How can advancements in managing heat dissipation impact future developments in semiconductor technology?

Advancements in managing heat dissipation play a crucial role in shaping the future of semiconductor technology. As computer components continue to shrink and become more powerful, the issue of overheating becomes increasingly significant. Efficient cooling methods are essential to prevent hotspots that can limit performance and reliability. By effectively dissipating heat from these localized areas, semiconductor devices can operate at higher speeds without risking damage due to excessive temperatures. This improved thermal management allows for increased power densities and enhanced overall performance of electronic systems.

What potential drawbacks or challenges might arise from using ultrathin silicon carbide for cooling electronic hot spots?

While using ultrathin silicon carbide for cooling electronic hot spots offers promising benefits, there are also potential drawbacks and challenges to consider. One major concern is the interface between silicon carbide and other semiconductor materials like silicon or gallium nitride, which may lead to thermal boundary resistance buildup. This resistance could hinder efficient heat transfer between the materials, reducing the effectiveness of the cooling solution. Additionally, manufacturing ultrathin silicon carbide layers with high quality and uniformity poses technical challenges that need to be addressed for practical implementation on a large scale.

How can innovative approaches like this in electronics influence other scientific fields?

Innovative approaches like utilizing ultrathin silicon carbide for thermal management in electronics have broader implications beyond just semiconductor technology. The development of advanced cooling techniques not only enhances the efficiency and reliability of electronic devices but also has ripple effects across various scientific fields. For instance, breakthroughs in thermal management can benefit industries such as aerospace engineering by improving the performance of onboard electronics under extreme conditions. Furthermore, innovations in one field often inspire cross-disciplinary collaborations leading to new discoveries and applications across diverse scientific domains such as materials science, nanotechnology, and renewable energy research.

0