Revolutionary 3D Printing of Shape-Specific Particles

핵심 개념

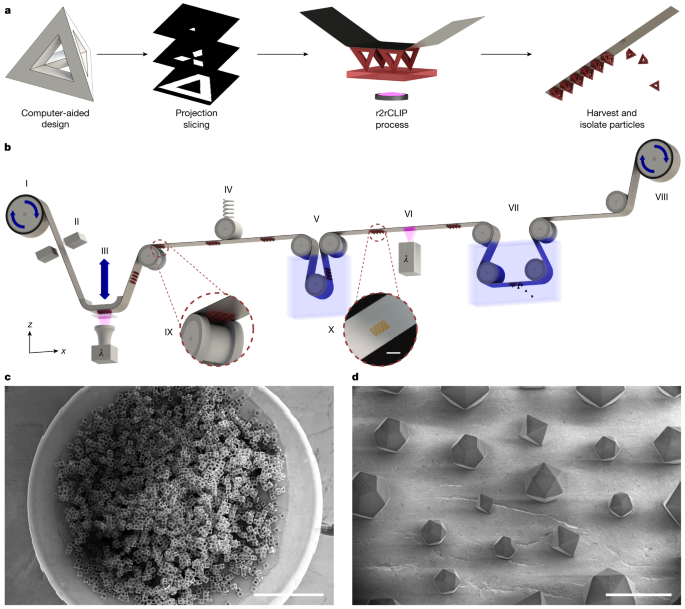

The author introduces a high-resolution, roll-to-roll 3D printing technique for creating shape-specific particles with complex geometries at a rapid pace. The main thesis is that this innovative method allows for the production of microscopic particles with intricate designs suitable for various applications.

초록

Particle fabrication has gained significant attention due to its wide range of applications in various fields such as bioengineering, drug delivery, microfluidics, and more. The content introduces a novel roll-to-roll 3D printing technique called r2rCLIP that enables the fabrication of shape-specific particles with complex geometries not achievable through traditional methods. This method showcases the production of both mouldable and non-mouldable shapes with extremely small voxel sizes and unsupported thickness, allowing for up to 1,000,000 particles per day to be created. These microscopic particles can be seamlessly integrated into biomedical, analytical, and advanced materials applications.

Roll-to-roll, high-resolution 3D printing of shape-specific particles - Nature

통계

We demonstrate r2rCLIP production of mouldable and non-mouldable shapes with voxel sizes as small as 2.0 × 2.0 µm² in the print plane.

At speeds of up to 1,000,000 particles per day.

인용구

핵심 통찰 요약

by Jason M. Kro... 게시일 www.nature.com 03-13-2024

https://www.nature.com/articles/s41586-024-07061-4

더 깊은 질문

How might the scalability of this new 3D printing technique impact industrial manufacturing processes

The scalability of the roll-to-roll continuous liquid interface production (r2rCLIP) technique in 3D printing shape-specific particles can have a significant impact on industrial manufacturing processes. By enabling the rapid and high-resolution fabrication of particles with complex geometries at speeds of up to 1,000,000 particles per day, this technique offers increased efficiency and flexibility in production. Manufacturers can benefit from the ability to quickly produce customized particles for various applications such as drug delivery systems, microfluidics devices, and advanced materials. The scalability of r2rCLIP allows for seamless integration into existing manufacturing workflows, leading to streamlined processes and reduced production times.

What challenges could arise from integrating these intricate design particles into biomedical applications

Integrating intricate design particles fabricated using techniques like r2rCLIP into biomedical applications presents several challenges that need to be addressed. One major concern is ensuring the biocompatibility and safety of these particles when used in biological systems. Thorough testing and evaluation are necessary to assess any potential toxic effects or immune responses triggered by these custom-designed particles. Another challenge lies in achieving precise control over particle properties such as size, shape, and surface characteristics to meet specific requirements for biomedical applications. Additionally, maintaining batch-to-batch consistency and reproducibility in particle fabrication is crucial for reliable performance within biomedical settings.

How could advancements in particle fabrication techniques like r2rCLIP influence future developments in microelectronics

Advancements in particle fabrication techniques like roll-to-roll continuous liquid interface production (r2rCLIP) hold great promise for influencing future developments in microelectronics. The ability to create shape-specific particles with micron-level resolution opens up new possibilities for designing novel electronic components with enhanced functionalities and performance characteristics. By leveraging r2rCLIP technology, researchers can explore innovative approaches to fabricate miniaturized electronic devices with tailored properties suited for diverse applications ranging from sensors and actuators to flexible electronics. This advancement could lead to breakthroughs in miniaturization, energy efficiency, and functionality within the field of microelectronics while offering new opportunities for creating next-generation electronic systems.

0