Advancements in High-Speed Stretchable Integrated Circuits

Główne pojęcia

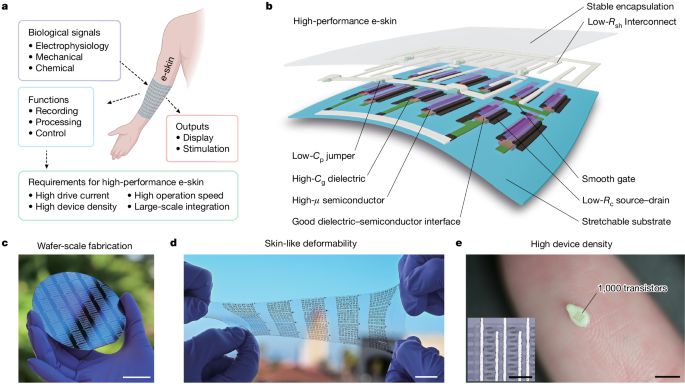

The author presents groundbreaking advancements in high-density, intrinsically stretchable transistors and integrated circuits, showcasing superior performance compared to current technologies.

Streszczenie

Innovations in materials, fabrication processes, device engineering, and circuit design have led to the development of intrinsically stretchable transistors with exceptional field-effect mobility, device density, and drive current. These advancements have enabled the creation of a large-scale integrated circuit with impressive capabilities such as high-speed stage-switching frequency and a braille recognition system that surpasses human skin sensing ability.

High-speed and large-scale intrinsically stretchable integrated circuits - Nature

Statystyki

Average field-effect mobility of more than 20 cm2 V−1 s−1 under 100% strain.

Device density of 100,000 transistors per cm2.

High drive current of around 2 μA μm−1 at a supply voltage of 5 V.

Large-scale integrated circuit with more than 1,000 transistors and a stage-switching frequency greater than 1 MHz.

Active-matrix tactile sensor array with a record-high density of 2,500 units per cm2.

Light-emitting diode display with a high refreshing speed of 60 Hz.

Cytaty

"Intrinsically stretchable electronics offer promising applications from continuous physiological monitoring to autonomous medical treatment."

"Our intrinsically stretchable transistors exhibit superior performance comparable to state-of-the-art flexible transistors."

Kluczowe wnioski z

by Donglai Zhon... o www.nature.com 03-13-2024

https://www.nature.com/articles/s41586-024-07096-7

Głębsze pytania

How might these advancements in stretchable electronics impact the future of wearable technology

The advancements in intrinsically stretchable integrated circuits have the potential to revolutionize the future of wearable technology. With high-density, high-speed, and large-scale integration capabilities, these stretchable electronics can enable a new generation of wearable devices that seamlessly conform to the body's movements. This could lead to more comfortable and unobtrusive wearables for continuous physiological monitoring, real-time health analysis, and even closed-loop medical treatments. The ability to achieve skin-like mechanical properties while maintaining excellent electrical performance opens up possibilities for applications in healthcare, fitness tracking, augmented reality, and beyond. Wearable devices incorporating these technologies could provide users with unprecedented levels of personalized data and feedback in a non-invasive manner.

What challenges could arise from the widespread adoption of intrinsically stretchable integrated circuits

While the widespread adoption of intrinsically stretchable integrated circuits holds great promise for wearable technology and beyond, several challenges may arise. One significant challenge is ensuring reliability and durability over extended periods of use. Stretchable electronics must withstand repeated stretching without compromising their functionality or structural integrity. Additionally, issues related to power consumption efficiency, signal processing accuracy under strain conditions, as well as scalability in manufacturing processes need to be addressed for mass production at an affordable cost. Furthermore, concerns regarding data security and privacy protection become crucial when dealing with sensitive personal information collected by wearable devices based on these advanced technologies.

How can innovations in materials science continue to push the boundaries of electronic devices

Innovations in materials science play a vital role in pushing the boundaries of electronic devices towards higher performance levels. By developing novel materials with superior mechanical flexibility combined with exceptional electrical properties like high carrier mobility or low resistance values under strain conditions can unlock new possibilities for device design and functionality. For instance, exploring advanced nanomaterials such as carbon nanotubes or two-dimensional materials like graphene can lead to enhancements in conductivity while maintaining flexibility required for stretchable electronics applications.

Moreover,

innovations

in fabrication techniques such as additive manufacturing processes or self-assembly methods can further streamline production workflows while reducing costs associated with traditional lithography-based approaches.

By continuously pushing the limits of material science research,

the development

of next-generation electronic devices will continue evolving towards more efficient,

reliable,

and versatile solutions across various industries including healthcare,

wearables,

Internet-of-Things (IoT),

and beyond.

0