Nanoscale Mechanical Device Releases Molecules on Demand

核心概念

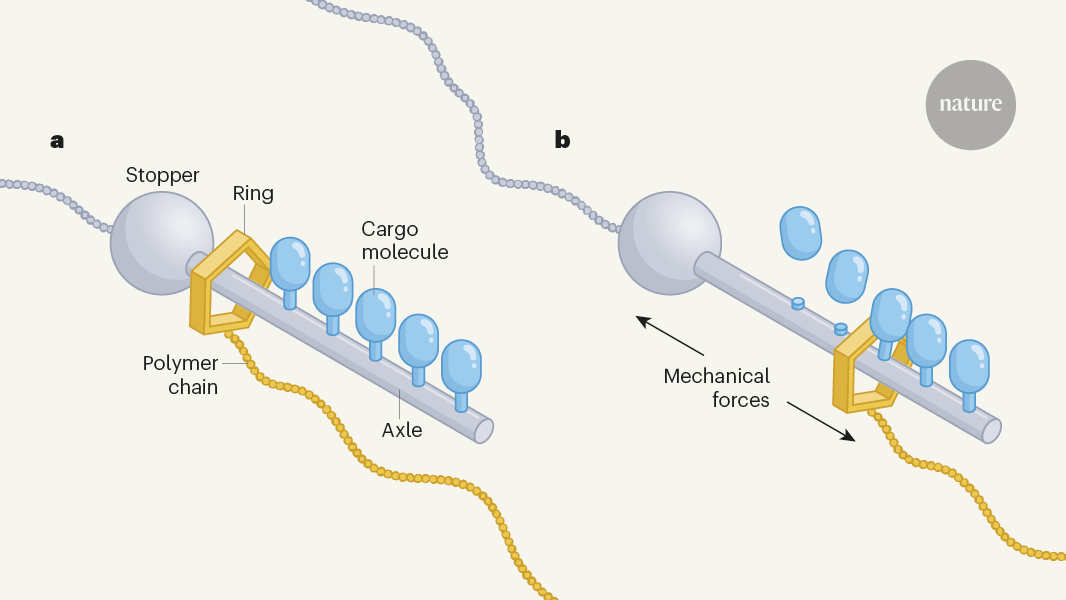

A nanoscale device can release cargo molecules when subjected to compressive forces or ultrasound, enabling potential applications in targeted drug delivery and industrial processes.

摘要

The article discusses the development of a nanoscale molecular device that can release cargo molecules in response to mechanical forces. This device offers an alternative to existing release mechanisms triggered by light, pH, or temperature changes.

The key highlights and insights are:

Nanoscale systems that can release molecules on demand have many potential applications, such as targeted drug delivery and industrial processes.

Existing release mechanisms often rely on triggers like light, pH, or temperature changes.

In recent years, mechanical forces have emerged as an alternative trigger for releasing small molecules.

The authors report a molecular device that can successively release cargo molecules when subjected to compressive forces or ultrasound.

This mechanically triggered release mechanism provides a new approach for controlled molecular release at the nanoscale.

Nanoscale scythe cuts molecular tethers using mechanical forces

統計資料

There are many potential applications for nanometre-scale systems that release molecules on demand.

These often involve release mechanisms that are triggered by irradiation with light, changes in physical parameters, such as pH or temperature.

In the past few years, mechanical forces have emerged as an alternative trigger for releasing small molecules.

引述

"There are many potential applications for nanometre-scale systems that release molecules on demand — for example, to deliver biologically active compounds to a specific compartment of the human body, or to dispense catalysts for use in an industrial process."

"Writing in Nature, Chen et al.4 report a molecular device that successively releases cargo molecules when compressive forces or ultrasound are applied."

從以下內容提煉的關鍵洞見

by Iwona Nieren... 於 www.nature.com 04-10-2024

https://www.nature.com/articles/d41586-024-00909-9

深入探究

How can the mechanical release mechanism be further optimized and scaled up for practical applications?

To optimize and scale up the mechanical release mechanism for practical applications, several strategies can be employed. Firstly, the design of the nanoscale device can be refined to enhance its mechanical responsiveness, ensuring that it can efficiently release cargo molecules under varying levels of compressive forces or ultrasound. This may involve the use of advanced materials with specific mechanical properties that can withstand repeated mechanical stimuli without degradation.

Furthermore, the integration of sensors or feedback mechanisms into the device can enable precise control over the release process, allowing for tailored release kinetics based on external stimuli. By incorporating smart materials that respond to specific mechanical cues, the device can be fine-tuned to release cargo molecules at desired locations and time points.

In terms of scalability, manufacturing techniques such as nanolithography and self-assembly can be utilized to produce large quantities of these nanoscale devices with consistent performance. By optimizing the fabrication process, the production of these devices can be streamlined, making them more accessible for widespread applications in drug delivery, catalysis, and other fields.

What are the potential limitations or challenges in using mechanical forces as a trigger for molecular release compared to other stimuli-responsive mechanisms?

While mechanical forces offer a promising approach for triggering molecular release, there are several limitations and challenges that need to be addressed. One key limitation is the potential for non-specific release of cargo molecules due to unintended mechanical stimuli. Unlike stimuli-responsive mechanisms that rely on specific triggers such as light or pH, mechanical forces can be more difficult to control precisely, leading to off-target release.

Another challenge is the potential for mechanical fatigue or wear and tear on the nanoscale device over time. Repeated application of compressive forces or ultrasound may cause degradation of the device, affecting its performance and reliability. Strategies to enhance the durability and longevity of the device, such as using robust materials or implementing self-repair mechanisms, will be crucial in overcoming this challenge.

Additionally, the complexity of integrating mechanical triggers into existing systems or processes may pose challenges in terms of compatibility and scalability. Ensuring seamless integration of the nanoscale device with target applications while maintaining efficiency and reliability will require careful design and optimization.

What other types of cargo molecules or payloads could be incorporated into this nanoscale device, and how might that expand its potential uses?

The incorporation of various types of cargo molecules or payloads into the nanoscale device can significantly expand its potential uses across different fields. For instance, biologically active compounds such as drugs or therapeutic agents can be loaded into the device for targeted drug delivery applications. By releasing these molecules in response to mechanical forces, the device can enable precise and controlled drug release at specific sites within the body, minimizing side effects and improving therapeutic outcomes.

In addition to drug delivery, the nanoscale device can be loaded with catalysts for use in industrial processes, enabling on-demand release of catalytic agents for chemical reactions. This could revolutionize the field of catalysis by providing a more efficient and sustainable approach to catalytic processes, with the potential for enhanced selectivity and yield.

Furthermore, the device could be tailored to release imaging agents for diagnostic purposes, allowing for real-time monitoring of biological processes or disease progression. By incorporating a diverse range of cargo molecules or payloads, the nanoscale device can be customized for various applications in healthcare, biotechnology, and materials science, showcasing its versatility and potential impact.

0